CNC Machinist Program

CNC Machinist is now offered on the Grayling campus

Stop for a moment and look around you.

You’re surrounded by objects that were made through machining processes. Unless you’re living a very rustic life in a cabin secluded in the woods and never go anywhere else, the products of machinists’ work are literally everywhere you look!

And, yet, our American workforce is currently in great need of MORE people to do this vital work, especially if we want to bring more manufacturing back to the United States.

If you’re curious about doing work that uses both your smarts and your hands-on skills, if you like to build things, and like the idea of working with technology, look closely at CNC Machinist. You may be surprised at what you find!

What is a CNC Machinist?

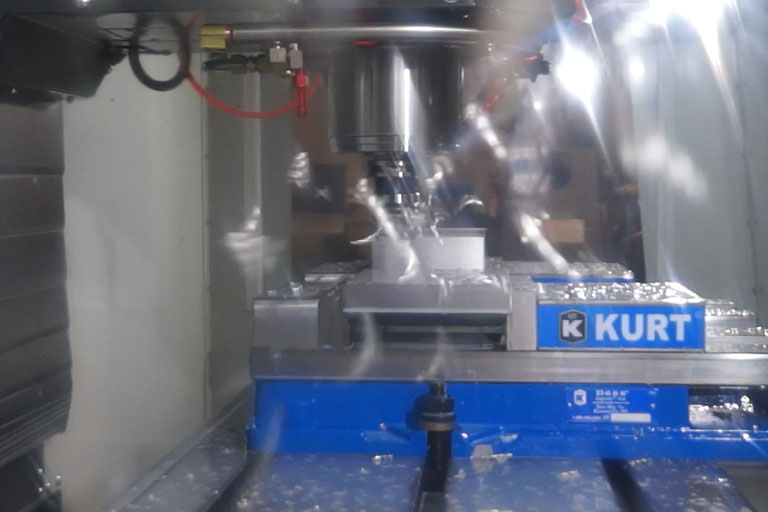

CNC machining is a manufacturing process that uses drills, mills, lathes and other cutting tools to systematically remove material from a piece of material to create a finished object or part. It begins with a hunk of metal or plastic and, after cutting away all the unnecessary material, what’s left is a perfectly shaped and cut object!

As Michelangelo famously said, “Every block of stone has a statue inside it, and it is the task of the sculptor to discover it.” Although Michaelango wasn’t using CNC machines or coded programs, the principle is the same.

CNC programming is the process of telling each machine how to cut out a specific shape and size from the hunk of material.

The CNC programming language is called G-code. G-code tells the CNC machine which path to take in cutting out a part. Once a machine is programmed for a specific part, the machine can usually cut it repeatedly and accurately.

CNC programming also uses M-code (machine control language). It’s used in combination with G-code to switch various machine functions off and on, such as telling the spindle when to rotate and when to stop. For example, here’s a short list of M-codes:

- M03 Spindle start in clockwise rotation

- M04 Spindle start in counterclockwise rotation

- M05 Spindle stop

- M06 Tool change

Learning G-code is much simpler than learning HTML coding and does not require a computer programming background. Most of the math you’ll be learning begins with the same math you did in middle school while graphing coordinate pairs. Remember the X and Y axes? That’s where it all begins.

Although you don’t need to be a computer wizard to do CNC programming, enjoying computers and working with technology is a must.

CNC Operators have specific duties and responsibilities that can vary from industry to industry. Generally, they’re expected to set up, adjust, and operate machine tools to perform machining operations. Most of this work is highly detailed and requires precision on the part of the machine and the operator. Depending on where you work and the kinds of parts you’re making, there are many decisions to be made about how to approach a new project. Everything is not always rote and completely spelled out for you. Although at times the work is repetitive, you’ll have many chances to improve your workflow using both your time management and logical skills. As one educator put it, the job of a CNC machinist “is like being an alchemist, sculptor and computer programmer all at once.”

Employers are hungry and eager to hire more men and women for these jobs!

Could this be the right direction for YOU?

Career Opportunities

Median Salary (2021) in Michigan: $46,870

Employment growth (2021-31): 11%

Salary data according to O*NET Online

Is this a program where YOU can use your problem solving skills, keep learning, and come out with a new profession?

If you agree with most of these ideas, the answer may be YES …

- I may already be a man or woman working in the field and need a credential or additional training to qualify for a new job or promotion.

- I may be coming directly from high school OR looking for a new profession after being in the workforce and realizing I need more skills to create the lifestyle I want.

- I like the idea of working on a job that has both physical and mental elements, where I can use my hands-on skills and also my analytical mind.

- I find it exciting to create things and see the finished product.

- I have strong problem solving skills.

- I have the discipline and focus to pay close attention to details.

- I’m able to do repetitive tasks.

- I enjoy collaborating with others, sharing ideas and learning from others on the job who may have more experience.

- I’m good at time management and have a strong work ethic.

- When things don’t go exactly according to plan, I adapt!

At Kirtland you’ll finish with:

Certificate of Completion in CNC Machinist

Your Kirtland education is respected by employers

- When we were building our program, employers had input into our program design as well as the types of skills our students should be taught. This input from industry is ongoing which ensures that what we’re teaching matches what employers are looking for.

- Area employers have demonstrated their confidence in Kirtland’s program many times by sending their employees here as part of their formal apprenticeship programs.

- Our instructors have industry credibility and years of experience.

- We have both manual and CNC machines that are similar to what can be found in industry.

You can get both sides of your CNC training here and work where you want

We teach both CNC programming/machine operation PLUS manual machining, a combination you will not find in all training programs.

With these skills and your training intact, because there’s a nationwide shortage of CNC programmers and machinists, your job prospects are excellent just about anywhere that manufacturing takes place on a large or small scale.

We’ve designed an evening-based program for hands-on learners

If you’ve ever attended a school where your educational needs as a hands-on learner were not well met, you’re in for a big surprise here at Kirtland. Hands-on learning is our specialty.

This program takes place in the evenings.

You’ll have significant advantages here as you pursue your new career

For commuters, our campus in Grayling is easy to access.

Because this program can’t be held online, the location is important. We’re located just off I-75 at Exit 251.

Small classes

At Kirtland, you won’t feel lost in an environment where there are large numbers of students vying for the instructor’s attention. Our class sizes are small enough that your instructor will know your name and take an interest in you.

Passionate student-focused advisors provide the guidance you need to succeed.

Our advisors are well-known among current and former students alike for their kindness and exceptional level of interest and commitment to each student’s success.

Kirtland makes it easier to work out the finances

You can save a lot of money by enrolling here. Our tuition rates are one-third the cost of most four-year schools and universities, which puts you at a real advantage!

We also have many resources for financial aid and professional staff who’ll help you apply.

Get help with your financial aid

You may be surprised by how simple it is to apply for government grants, scholarships and loans.

Your credit history is not a major consideration in qualifying for federal aid. You DON’T need to attend school full-time to qualify. And we will assist you with the process you’re dreading IF you need help. Often students are eligible for more money than they’re expecting.

Your path to a lucrative & fulfilling future

Step 1 — Get Started

Apply for admission to the college. Apply for financial aid. p.s. If you need assistance with your financial aid application, we’re here to help!

Step 2

Speak to an advisor!

They’ll help you navigate the process, dot the I’s and cross the T’s! Declare CNC Machinist as your program of study.

Step 3

Complete your coursework.

Step 4

Celebrate! Graduate with your Certificate of Completion in CNC Machinist. Another milestone!

FINAL STEP

Go out and get a job, apply for a promotion, or otherwise put your new credential to work for you. Good luck!